By Ryan Hunter

After years of work untangling government bureaucracy, we at the City Performance Lean Program have a secret to share: the most lasting change comes not from a software implementation or a strategic plan, but from engaging employees to improve the nitty-gritty, on-the-ground, day-to-day work.

City Performance, a division of the San Francisco Controller’s Office, helps City departments become more effective and efficient in providing services to the public, from issuing permits to cleaning the streets. But some years ago, we had a problem: Client departments frequently asked us to help map broken, bureaucratic City processes, and we delivered beautiful flowcharts and reports full of recommendations… but little would change on the ground. So in 2015, we founded the City Performance Lean Program asking a simple question that’s incredibly hard to execute: How can we get City employees to own change and solve their own problems?

To tackle this challenge, we turned to lean, a problem solving and process improvement methodology that originated in Japan with Toyota but has since spread to healthcare and, more recently, government. Using lean principles, we coach San Francisco city staff at all levels of the organization to identify the core value their departments provide to citizens, to eliminate process steps that aren’t adding value, and to build continuous improvement into their daily work.

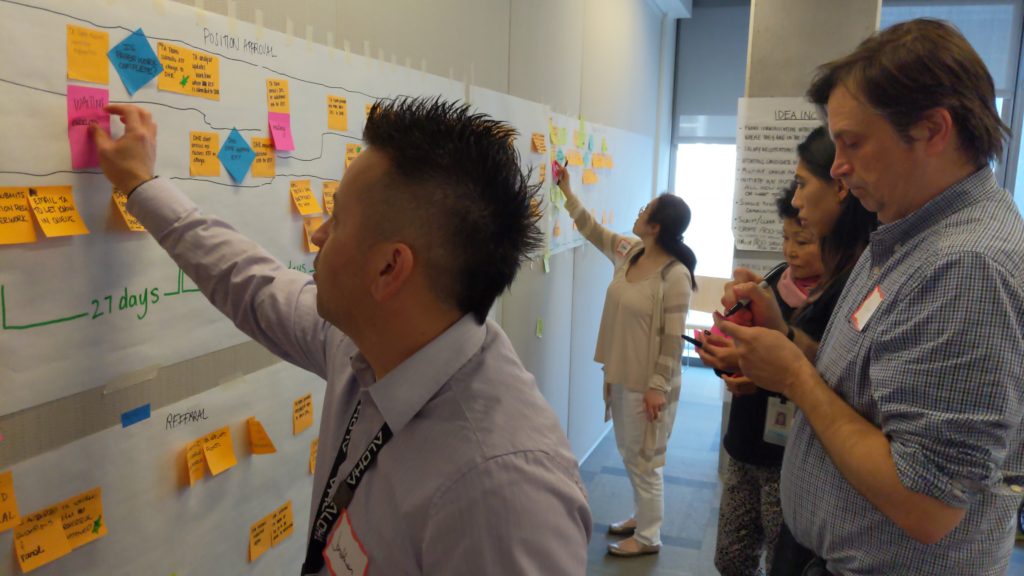

In one of our first lean improvement events, we coached a human resources group to streamline civil service exams. As we walked them through mapping their exam preparation process (with sticky notes on butcher paper), we discovered that one of the admin staff was spending a full day before each exam sharpening pencils to give to candidates! Not only was this pencil sharpening a waste of time, it was also disrespectful to a talented employee – and expensive! One of the HR team members suggested buying pre-sharpened pencils. Turns out that 500 pre-sharpened pencils cost $20 – far less than the cost of a day of staff time. It’s this “aha” moment we go for – the moment when a front-line staff has an idea that makes life better for both staff and citizens and has been empowered by leadership to make a change.

Four years into our own lean journey, we’ve trained over 600 staff, run partnerships with a dozen different City departments, and coached front-line staff to implement countless small improvements to make government processes a little smoother for our employees and the public. In partnership with our team, parks maintenance staff reclaimed over 10,000 square feet of storage space by identifying and disposing of 75 tons of obsolete, broken, or excess materials. Our contracting group cut in half the time needed to evaluate an RFP. Our transportation planners made an opaque public notification process easy to understand.

Some lean principles seem counter-intuitive: We should be looking to make our problems more visible, not less, because seeing our problems clearly helps us improve. When I tell our Lean 101 trainees the pencil story, they snicker – at least until I ask them what I’d find if we looked under the hood in their department. The truth is, unless your organization has a robust culture of continuous improvement, you too have something like the pencil sharpening in your organization. And it’s a gift to find it – we were able to give that admin staff a whole day back!

Another of our core principles: People are our most valuable resource. We begin our lean partnerships not by creating an expert analysis, but by building the analysis skills of the whole department’s staff. We seek to draw out the natural problem-solving capacity of front-line staff, asking them to submit and complete “Just-Do-It” innovations. The staff that take our intensive Lean Leaders training have often been tapped by their departments for promotion or to take on special projects. A couple of our training alumni even went to a lean conference in Japan to learn directly from Toyota! Before he left, one of them told me, “I’m going to bring this back. It’s to serve the people of San Francisco… I want to be able to share the magic that I’ve been experiencing of reducing struggle, eliminating waste, and continuous improvement.”

We’ve developed a Lean Toolbox that includes facilitation guides for a number of lean tools, and we’re always happy to share what we’ve learned with innovators in other cities. You can contact us through our website at cityperformanceleanprogram.weebly.com or me directly at ryan.hunter@sfgov.org.

Happy innovating!